In the past, the windows in the house were all made of paper, so the cost was low and the visibility was also low. Moreover, the thermal insulation is not good. With the continuous development of technology, glass has begun to enter thousands of households, bringing light to everyone, but also bringing certain hidden dangers, because the glass is prone to sharpness when it is broken. The debris, scratches the skin when in contact, or causes damage to people in the process of splashing. Therefore, in the process of continuous development of the current glass technology, such dangers are avoided, so that better glass appears.

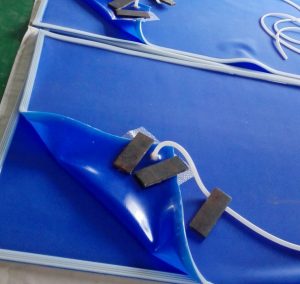

Now the main glass in the market is flat glass, laminated glass and tempered glass. The production process of laminated glass is also very simple. It is the combined use of Silicone vacuum bag for glass laminating furnace. In the process of heating under vacuum at high temperature, two flat glasses are laminated together with film to form a comparison. Thick laminated glass. If such glass is impacted by external force during use, the silicone vacuum bag covered by itself and the film inside will have a certain buffer, so that the glass can withstand a certain degree of external force, even if it is broken Cracks can also stick to the film without splashing.

Nowadays, large buildings or high-end shopping malls use this kind of high-end laminated glass or tempered glass, and the glass itself has low pressure resistance, but after using the silicone vacuum bag, the elasticity of the product itself is used to resist Compressibility, to achieve the protection of the glass itself, coupled with the abrasion resistance and acid and alkali resistance of the silicone vacuum bag itself, so that the glass is not affected and corroded by the external environment during use. At the same time, the service life of the glass is increased.

The use of Silicone vacuum bag for glass laminating furnace to make glass can reduce heat loss, ensure temperature balance during processing, and achieve a unique heat preservation effect. It can maintain an effective vacuum effect even in the event of a sudden power failure.