Basic information

Requirements for hot stamping silicone sheets: High temperature resistance of 300~400℃, hardness requirements can be determined according to the customer’s printing pattern requirements. Generally, the hardness is 30A°, 40A°, 50A°, 60A°, 70A°, 80A°, 90A°, etc.

Performance

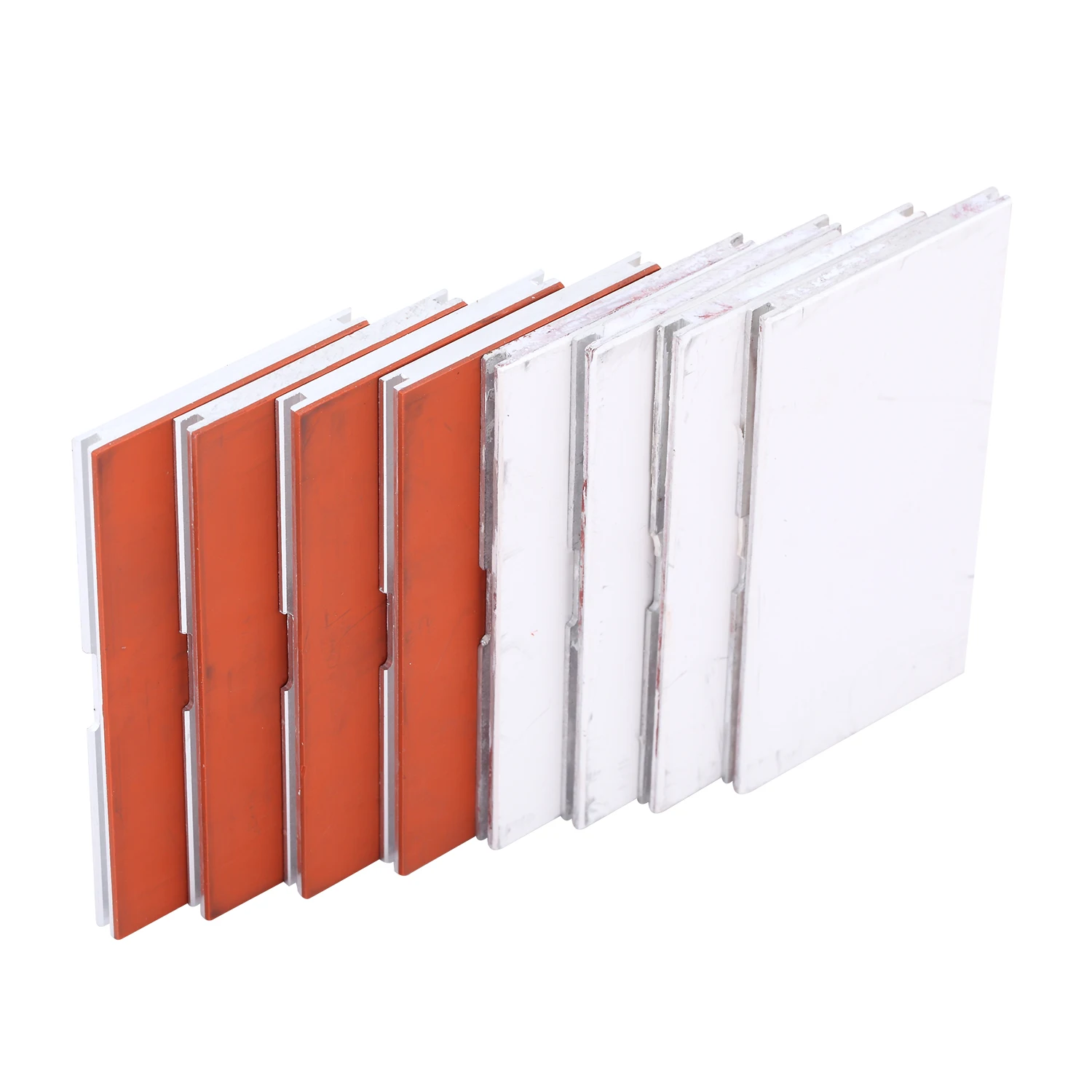

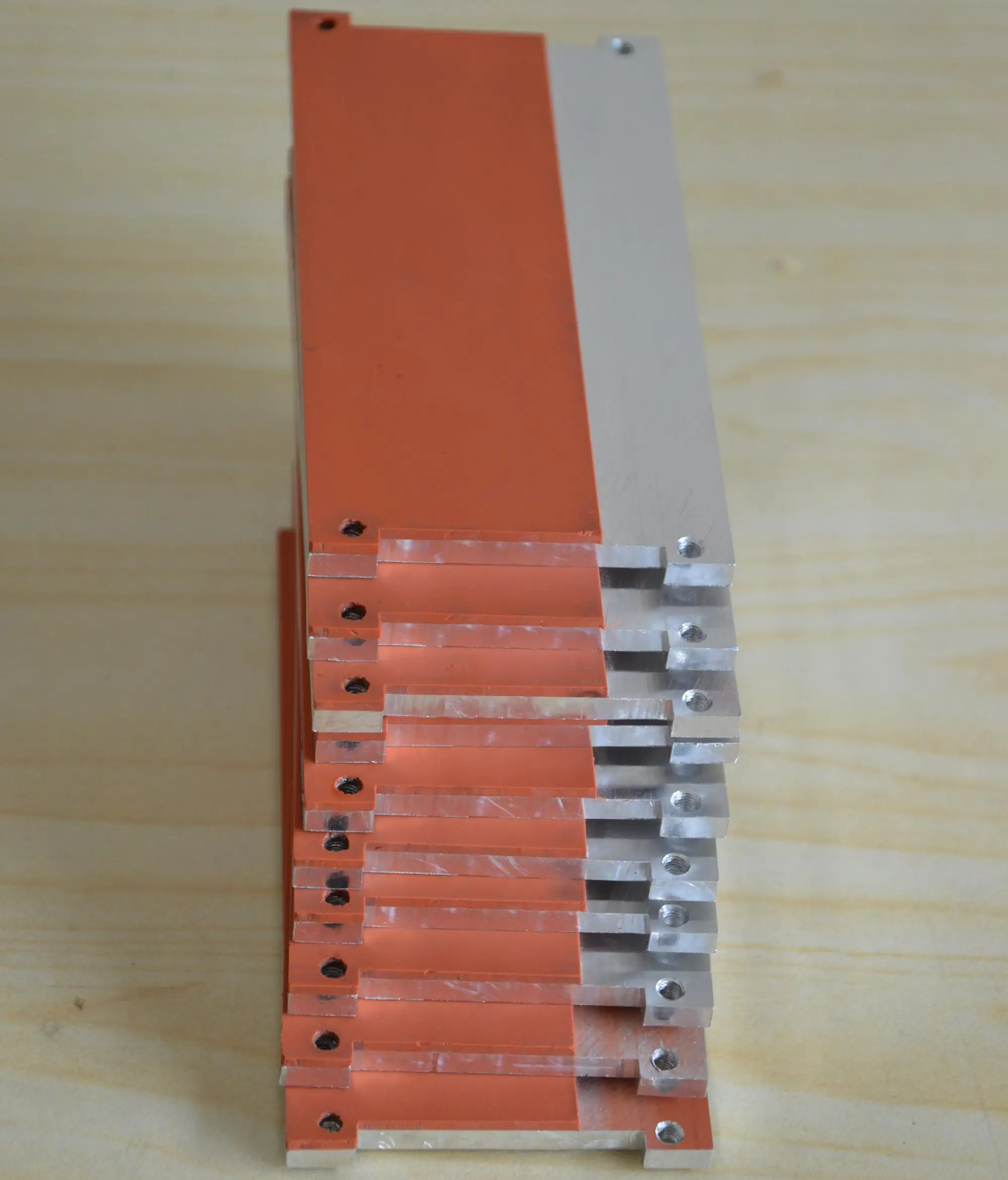

The hot stamping silicone plate is a product matching the hot stamping equipment. It uses the silicone plate as a heat carrier to transfer exquisite patterns to the product. There are four colors: red, orange, white and black. It has the characteristics of high temperature resistance 300-400℃, high pressure resistance, high thermal conductivity, good elasticity and high temperature resistance.

Purpose

Mainly used in hot stamping fields such as wine bottle caps, plastic discs, plastic cups, cosmetic boxes and other plastic parts and hardware. The hot stamping silicone plate plays a heat transfer role. Through the heat transfer of this product, the hot stamping paper is printed on the object to be ironed.

Type

There are two types of hot stamping boards: one is made of silicone and aluminum boards pasted together; the other is without aluminum boards, and only silicon is used to produce sheets.

Specifications

Width*length*aluminum*glue+degree

300mm width*600mm length*(0.5mm aluminum-30mm aluminum)*(1mm glue-20mm glue)

Supports customization, special specifications and thickness can be customized.

Silicone plate is different from other materials

Silicone plates differ from plates made of traditional materials like plastic, glass, ceramic, and metal. Silicone plates are exceptionally durable, resistant to breaking, and flexible. They can withstand extreme temperatures, from freezing to microwave heating, without deformation. Silicone is generally considered safe, being free from harmful chemicals like BPA and phthalates. Cleaning silicone plates is a breeze, often dishwasher-safe and resistant to staining. In contrast, materials like plastic may contain potentially harmful chemicals, glass and ceramics can be fragile, and metals can react with acidic foods. The choice depends on individual preferences and specific requirements, such as durability and safety considerations.

FAQ

1. Who are we?

We are based in Guangdong, China, starting in 2014, sell to Southeast Asia(50.00%), and North America(50.00%). There are a total of about 11-50 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. What can you buy from us?

silicone rubber roller, roller Blocking silica, silica gel ink roller, Blocking silica plate, plate heat transfer silica

4. Why should you buy from us not from other suppliers?

Our company is a company specializing in the production of silicone rubber rollers, roller-blocking silica, silica gel ink rollers, blocking silica plates, plate heat transfer silica, silica gel plates of silica products, and other high-technology enterprises.

5. What services can we provide?

Accepted Delivery Terms: FOB, CFR,CIF, EXW,FAS, CIP,FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram, Credit Card,PayPal, Western Union,Cash, Escrow;

Language Spoken:English, Chinese